Zuckermühle Hersteller

-

WLF Zuckermühlenmaschine Maschine

Raffinierte Kontrolle, raffinierter Zucker: Konsequente Granulation: Im Gegensatz zu im Laden gekauften Zucker mit unterschie... -

WLF Horizontaler Zuckermühlenmaschine

Diese Maschine wird hauptsächlich in der chemischen Industrie, Medizin (TCM), Lebensmittel, Gewürzen, Harzpulver, Besmierenpulver, Sexmat... -

WLF -Zyklon -Zuckermühle Maschine

Die WLF -Zyklon -Zuckermühle -Maschine geht über den gerechten Zucker hinaus. Hier ist ein tieferer Eintauchen in seine Funktionen und wa... -

WLM Automatische Ultra feine Zuckerpulverherstellung Maschine

MICRO -Mühlentechnologie: Das WLM verfügt über ein revolutionäres Schleifsystem, das herkömmliche Einschränkungen zerstört. Hochgeschwind... -

WLF billige Preis Zuckermühle Maschine

Die Zuckermühle besteht aus WLF-Pin-Mühlenmaschine, die einfachste Schleifmaschine, die Zucker zu Pulver 12-120 mesh mahlen kann. The pin... -

WLF Horizontale Zuckerpulvermaschine herstellen

Diese Zuckerpulverherstellung ist horizontaler Typ. Wenn die Maschine arbeitet, wird das Zuckerpulver direkt aus dem Entladungsteil ausge... -

WLF Zucker Gewürzmühle Stiftmühle Maschine

Die Gewürzschleifermaschine kann Zucker zu Pulver mahlen, die Pulvergröße ist einstellbar, sie kann von 12 Mesh bis 120 Mesh. Die Kunden ... -

WLM Automatische Zuckerpulvermaschine für Vereisungspulver

Die automatische Schleifmaschine kann den Zucker zu einem sehr sehr feinen Pulver, mehr als 200 Mesh, mahlen. Beim Mahlen von Zucker könn...

Über uns

Ehre

-

Ehre

Ehre -

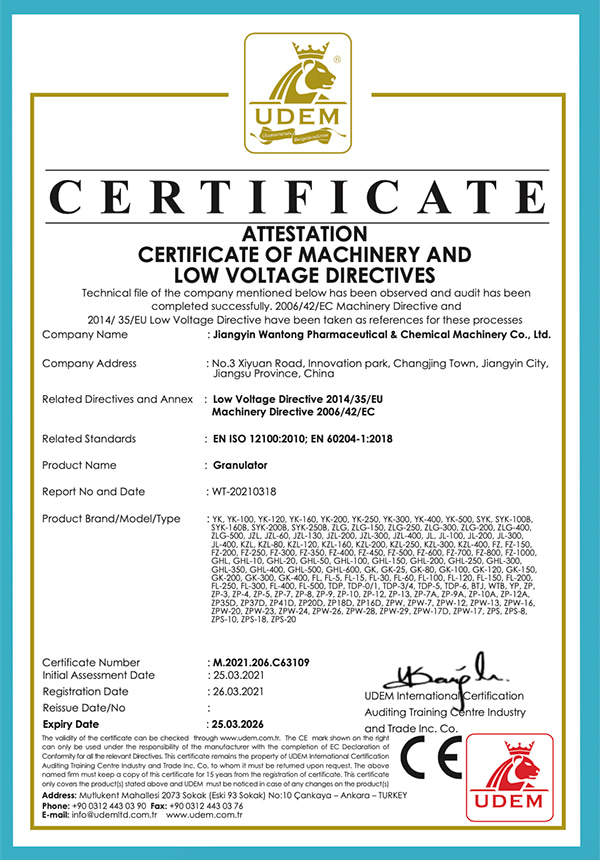

Ce

Ce

Nachricht

-

Branchennachrichten 2026-01-06

Einführung in Gewürzmahlmaschinen Mahlmaschinen für Gewürze sind unverzichtbare Geräte s...

Mehr anzeigen -

Branchennachrichten 2026-01-04

Einführung in industrielle Trocknungsmethoden Das Trocknen ist ein kritischer Prozess in der p...

Mehr anzeigen -

Branchennachrichten 2025-12-23

Einführung in Doppelkegelmixer Doppelkegelmischer sind weit verbreitete industrielle Mis...

Mehr anzeigen -

Branchennachrichten 2025-12-18

Einführung in Gewürzmahlmaschinen Gewürzmahlmaschinen sind unverzichtbare Werkzeuge für ...

Mehr anzeigen

Branchenwissen Expansion

What strategies can be used to improve the energy efficiency of sugar milling operations?

Improving energy efficiency in sugar milling operations is crucial for reducing costs, enhancing sustainability, and minimizing environmental impact. Here are some effective strategies to achieve this:

Process Optimization

Automated Control Systems:

Implementing automated control systems can significantly enhance the energy efficiency of sugar milling operations. These systems continuously monitor and adjust process parameters in real-time, ensuring optimal performance and reducing energy wastage. By maintaining precise control over the milling process, mills can minimize energy consumption while maximizing output.

Process Integration:

Integrating various processes within the milling operation can lead to substantial energy savings. For example, waste heat from one stage of the process can be used to preheat materials in another stage. This integration reduces the overall energy demand by making efficient use of available heat and reducing the need for additional heating sources.

Equipment Upgrades and Maintenance

High-Efficiency Equipment:

Investing in high-efficiency motors, pumps, and boilers is a straightforward yet impactful way to enhance energy efficiency. Modern equipment is designed to operate more efficiently, using less energy to perform the same tasks as older, less efficient models. Upgrading to such equipment can lead to significant reductions in energy consumption.

Regular Maintenance:

Regular maintenance of equipment is essential to ensure it operates at peak efficiency. Over time, equipment can become less efficient due to wear and tear, dirt buildup, and other factors. Regularly cleaning and servicing equipment like heat exchangers, boilers, and turbines helps maintain their efficiency, thereby reducing energy consumption.

Cogeneration and Renewable Energy

Cogeneration:

Cogeneration, or combined heat and power (CHP), is a highly efficient energy system that produces electricity and useful heat simultaneously from the same energy source. In sugar mills, bagasse (the fibrous residue from sugar cane) can be used as a fuel for cogeneration. This not only provides a renewable energy source but also maximizes the energy extracted from the biomass.

Renewable Energy Sources:

Incorporating renewable energy sources such as solar panels or wind turbines can further improve the energy efficiency of sugar milling operations. These renewable sources can supplement the energy needs of the mill, reducing dependence on fossil fuels and lowering overall energy costs.

Heat Recovery and Insulation

Heat Recovery Systems:

Installing heat recovery systems can capture and reuse waste heat from various processes within the mill. For instance, waste heat from boilers can be used to preheat incoming water or air, reducing the energy required for heating. This reuse of energy improves overall efficiency and reduces the mill's energy footprint.

Improved Insulation:

Enhancing the insulation of equipment and pipelines helps in retaining heat, thereby reducing the energy needed to maintain desired temperatures. Proper insulation minimizes heat loss, ensuring that more of the energy produced is used effectively within the milling process.

By adopting these strategies, sugar mills can significantly improve their energy efficiency. Process optimization, equipment upgrades, cogeneration, renewable energy integration, and effective heat management are all critical components of a comprehensive approach to energy efficiency. These measures not only lower operating costs but also contribute to the sustainability and environmental responsibility of sugar milling operations.

How to manage wear on sugar mill grinding equipment?

Wear on grinding equipment in sugar mills is a significant challenge, affecting efficiency, productivity, and maintenance costs. Effective management strategies are crucial to ensure the longevity and optimal performance of the equipment. Here are key strategies to manage wear on sugar mill grinding equipment:

Regular Maintenance and Inspection

Scheduled Maintenance:Implementing a routine maintenance schedule is essential. Regular inspections and servicing can identify early signs of wear, allowing for timely interventions. This proactive approach helps in preventing unexpected breakdowns and extends the lifespan of the equipment.

Wear Monitoring:Utilize wear monitoring techniques such as ultrasonic testing, vibration analysis, and thermal imaging. These methods provide real-time data on equipment condition, enabling predictive maintenance and reducing downtime.

Material Selection and Protective Coatings

High-Quality Materials:Using high-quality, wear-resistant materials for critical components like rollers and crusher plates can significantly reduce wear. Materials such as alloy steels and tungsten carbide are known for their durability and resistance to abrasion.

Protective Coatings:Applying protective coatings like hardfacing or ceramic coatings to wear surfaces can extend the life of grinding equipment. These coatings provide a hard, wear-resistant layer that protects the underlying material from abrasion and erosion.

Design Improvements and Upgrades

Component Design:Optimizing the design of grinding components can reduce stress concentrations and enhance durability. Design improvements, such as using larger roller diameters or better load distribution mechanisms, can minimize wear.

Modular Components:Implementing modular design for components makes it easier to replace worn parts. This reduces downtime during maintenance and ensures faster restoration of normal operations.

Lubrication and Cooling

Proper Lubrication:Adequate lubrication of moving parts is crucial to reduce friction and wear. Using the appropriate type and grade of lubricant ensures smooth operation and protects against wear.

Cooling Systems:Effective cooling systems help in dissipating heat generated during grinding, which can accelerate wear. Implementing water or air cooling mechanisms can maintain optimal operating temperatures and reduce wear.

Operational Adjustments

Load Management:Monitoring and adjusting the load on grinding equipment to avoid overloading is essential. Ensuring that the equipment operates within its designed capacity prevents excessive stress and wear.

Feedstock Quality:Ensuring that the feedstock (sugar cane or beet) is properly prepared before grinding can prevent damage to the equipment. Removing stones, metal debris, and other foreign objects reduces the risk of wear and tear.

Staff Training

Operator Training:Training operators on best practices for operating and maintaining the grinding equipment can significantly reduce wear. Proper usage and handling techniques help in minimizing unnecessary stress on the equipment.

Maintenance Staff Training:Ensuring maintenance staff are well-trained in the latest techniques for inspecting and servicing the equipment is vital. Keeping up-to-date with the latest maintenance technologies can improve wear management.

By implementing these strategies, sugar mills can effectively manage wear on grinding equipment, ensuring smoother operations, reduced downtime, and lower maintenance costs. Regular maintenance, high-quality materials, protective coatings, design improvements, proper lubrication and cooling, operational adjustments, and comprehensive staff training are all critical components of an effective wear management program. These measures collectively contribute to the longevity and efficiency of sugar mill grinding equipment.